With Packaging Cockpit you manage your packaging worldwide

Our solution

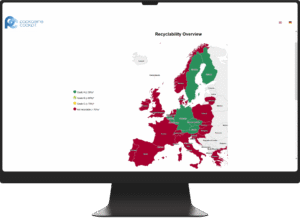

- Calculation of technical recyclability according to country-specific D4R guidelines (e.g., Circular Packaging Design Guideline, German Minimum Standard) and disposal infrastructures

- Streamlined life cycle assessment (cradle-to-grave and cradle-to-gate) incl. 16 impact categories (according to PEF)

- Determining licence fees and the plastic tax

- Currently calculating for 25 international countries (focus on EU)

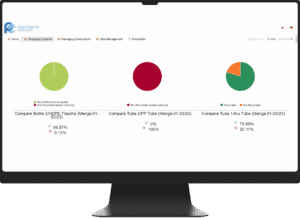

- Presenting calculation results in comparison

- Evaluating entire product portfolios aggregated over the sales period

- Constant exchange with international partners from science and industry

- Annual update to the latest scientific, technical and regulatory standards

- International application to enable global players to use a standardised specification management software

- Versatile and user-friendly input options

- Smart system structure

- Can be used for packaging in a wide range of areas

- Structure of packaging from material to system level (including industrial and transport packaging)

- Automated reporting for your specification data in PDF format

- Scientific service for packaging optimisation

- Software support for the correct entry of your portfolio

- Long-term consulting projects for a packaging portfolio in accordance with existing and future PPWR requirements

- Recyclability certificates

- Continuous updates to the latest PPWR developments

- Consultancy support from our scientific partner Circular Analytics GmbH

- Interface solutions with ERP and PIM systems (incl. backend calculation engine)

- Excel bulk data upload for convenient creation of your data already available in Excel format

- Import/export function between Packaging Cockpit accounts with authorisation system for secure data exchange between companies (e.g. between producer and retailer)

- Complete supply chain integration (supplier platform)

- Supplier onboarding to enable your suppliers to get started using the software easily

- Information security concept

Both the web interface and the underlying infrastructure are optimised for maximum performance, and we are constantly working to improve them even further. All services and databases run on the latest server systems and, if necessary, the load is distributed between the servers in the cluster so that we can react to peak loads and ensure smooth operation even at higher usage frequencies. A REST interface is also available for connecting external systems to import and export data.

The topic "data security" is very important to us. All data is stored in a data center in Vienna. Data is also backed up to another data center once a day to ensure that the system can continue to operate even in the event of a fire. In addition, so-called transaction logs are kept in order to be able to restore the data from any point in time and access to the data by unauthorized third parties is prevented by a multi-level procedure.

See also our frequently asked questions:

Data records can be created in the Packaging Cockpit in various ways:

- Manual data entry

- Packaging systems can be created and specifications entered in the intuitive user interface of the Packaging Cockpit

- Import from suppliers

- We are happy to assist you in conveniently providing the data via an interface

- Copying an existing data record and changing the necessary details

- The data management area of the Packaging Cockpit enables clear management of data records within a folder structure. Here, data records can be copied, sorted and individually structured

- Excel template transfer

- The data can be easily transferred to the Packaging Cockpit via an Excel import

- Managed service interface: customer software, e.g. an ERP (Enterprise Resource Planning) system, can be connected at any stage

To calculate recyclability and the life cycle assessment, you need to enter some important specifications. Mandatory fields are marked with an *. An overview of the most important data is listed below:

- The materials used and their weights

- Dimensions

- Manufacturing processes for the individual components

- Colour and printing

- Detailed queries about the individual components

- Adhesion and solubility

- Surface coverage of the main body by decorations

- Separability

- Country of manufacture

- Get in touch with a contact person

- We will clarify with you whether it is more advantageous for you to use the web application or a built-in solution (e.g. SAP) in one of your existing systems. Depending on the application, we will be happy to explain the next steps to you.

No, it is also possible to transfer Lean Spec Datasets

- These contain only the key data of the packaging and, optionally, the results of calculations of recyclability and life cycle assessment data

- The Lean Spec Datasets provide the most important information but cannot be used to perform calculations. This also makes it more difficult to imitate the packaging

The Packaging Cockpit already supports a large number of countries and is being continuously expanded. Our team is constantly working to integrate additional markets and regions in order to best meet your requirements.

Distribution countries:

- EU countries (currently 21 EU countries)

- Switzerland

- Norway

- United Kingdom

- Australia

- The Packaging Cockpit is technically designed according to the latest information security principles

- External parties have no access to your data

- Data is transferred from suppliers to customers within the system

- You decide in the authorisation module which of your customers receive which data records

Data security is our top priority. All data is stored in a data centre in Vienna, Austria and additionally backed up daily in a second data centre. Transaction logs enable recovery at any time. A multi-level security concept protects against unauthorised access.

- Get in touch with a contact person

Our basic version is available free of charge.

Additional features and upgrades can be purchased in our web shop (e.g. additional users or sales countries, recyclability certificates or a wide range of consulting services). You can access our web shop via the Packaging Cockpit tool.

The Packaging Cockpit is continuously developed and regularly updated. This is based on ongoing regulatory research that takes into account relevant changes in key legislation - such as the PPWR, relevant guidelines and country-specific requirements - and integrates them into the calculation logic.

The further development of the Packaging Cockpit is continuously based on current developments and future requirements of the PPWR. Once the relevant criteria have been finalized, the tool is designed to enable an assessment of packaging compliance with the PPWR.

In addition, a standardized framework is being developed to clearly and transparently incorporate additional content and requirements, such as the definition of key technical terms or minimum data requirements.